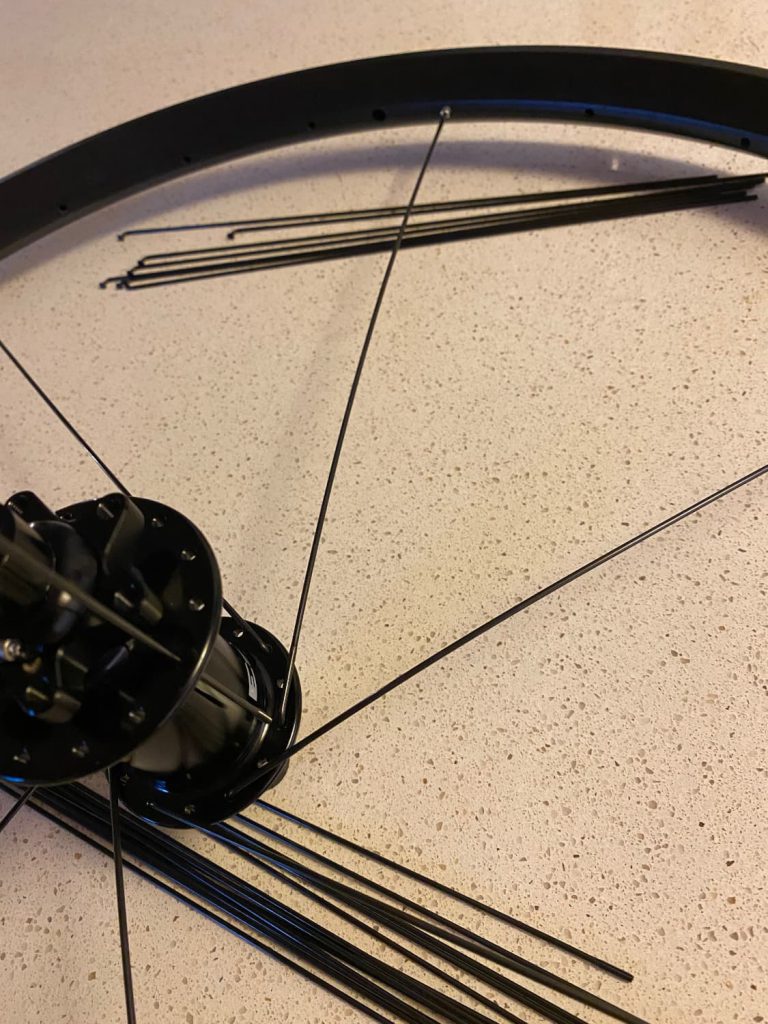

A few tips on how you can build a wheel yourself.

Preparations

Lay out the correct number of spokes, nipples, hubs, rims and any washers. Mark which ones are which.

Tips on tools

Ruler, easier to measure the length and thickness of spokes.

Spoke wrench

Possible directional rack

Spoke tension gauge

Dish tool to easily check that the wheel is centered

Step 1

Start on the side that has the most power, on the rear wheel you start on the drive side and the front wheel on the brake side

Turn the power side towards you

Find the hole most centered in the log

Count the number of crosses to the left, if the wheel is 3 crosses count 3 to the left and put in spokes with the head on the outside

Keep track of which is the main spoke.

Find the valve hole on the rim, and insert the spoke into the first hole to the left of the valve. If you have an asymmetrical rim, check that it is facing the right way.

Install every second spoke in every fourth hole

For asymmetric rims, it is important to turn the rim correctly. On a rear wheel, the wider side must face the drive side, and vice versa on the front rim, i.e. the wider side faces the disc side.

If you have followed all the steps, one bearing should be spoke and you should be able to see the logo through the valve hole.

step 2

Turn the wheel, and turn the hub so the main spoke is in the correct direction, straight down from the valve so as not to cross the valve.

Find the main spoke, and meet it on the opposite side of the hub, and find the first spoke hole on the right.

Insert a spoke with the spoke shell on the outside of the hub.

Drop in a spoke in every second hole, and mount to the right of the spoke.

Turn the hub so you can see the logo through the valve hole

Step 3

Drop in spokes in remaining holes on power side. Depending on the number of crushes, if you have 3 crushes, you count 2 crushes over and one under.

Step 4

Drop in spokes in remaining holes on opposite side. Depending on the number of crushes, if you have 3 crushes, you count 2 crushes over and one under.

If you followed all the steps, you should now have a fully spoked wheel

Direction

Start by dropping a drop of oil on each spoke, which runs down into the spoke. To make it easier to tighten

The first step then is to get all the nipples to the same height, a tip is to try to put them all where the thread is no longer visible.

Then start by going around the entire wheel and turning 1-2 turns on each spoke, until you feel tension. Check if the wheel is in the middle, otherwise turn 1-2 turns on the side that needs to be moved.

Then you continue working around the wheel

To get the rim centered (disched) If the rim is to the left, tighten on the opposite side

To remove the egg shape, tighten where it goes up and release on the opposite side

Mash the wheel, and check the wheel again.